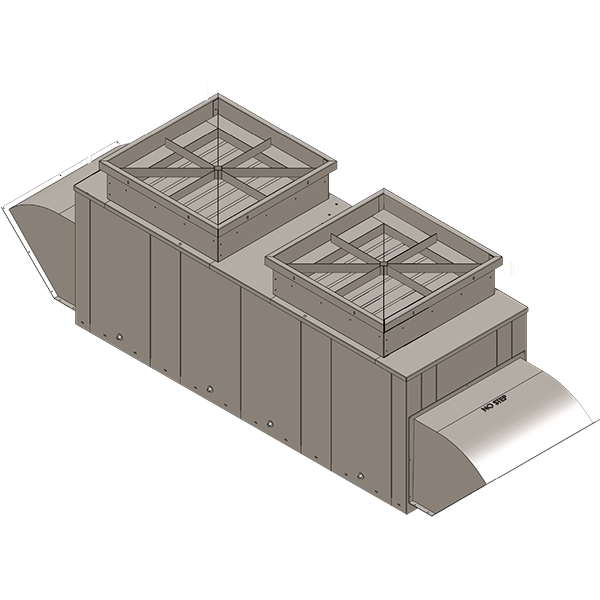

Exhaust Plenums

Efficient Airflow Distribution with Engineered Plenum Design

Plenums are typically utilized as the initial contact point for exhaust air entering an exhaust fan system. A plenum is a large duct where air velocities are low. Our plenums can be selected as either bottom or side inlets. Well-designed plenums reduce turbulence, promotes consistent exhaust velocity, and enhances overall system performance. We offer custom plenum designs to easily retrofit into system.

- Single & Double Wall Plenums

- Plenum Inlet Options

- Specialized Applications

Single Wall Plenums

Single walled plenums are made from one layer of construction materials which will vary based on exhaust application. Single wall plenums are lighter allowing for easier install and are ideal for applications where insulation, sound attenuation, and temperature are not top priorities.

Double Wall Plenums

Double walled plenums are made from multiple layers of construction material separated by an insulating material. These plenums are heavier than single wall plenums. Double wall plenums are ideal for applications requiring sound attenuation, thermal control, or condensation are concerns.

Bottom Inlet Plenums

Bottom inlet plenums are sized and selected to have a maximum velocity through the opening of 1,500 fpm. Bottom inlet opening allows for air to travel unrestricted straight up into the exhaust fan inlet and therefore has a higher allowable velocity than side inlets.

Side Inlet Plenums

Side inlet plenums are sized and selected to have a maximum velocity through the opening of 1,200 fpm. The side inlet opening causes the inlet air stream to do a 90 degree turn upwards in order to enter the exhaust fan inlet. This direction change for the inlet air stream results in a slightly more restricted flow path and therefore is sized at a lower velocity to maintain proper distribution of exhaust air to the inlet of each exhaust fan.

Diesel Exhaust Fan Applications

In diesel generator exhaust applications, the inlet duct work is not directly connected to the inlet of the fan system plenum to allow exhaust temperature to be diluted with ambient air and prevent back pressure onto the diesel generator itself. This high temperature application will require plenum materials to be coated with high temperature coating and the plenum construction materials will need to be suitable for high temperature applications.

Plenums doors are not supplied for high temperature applications because they’re not rated above 300°F. To maximize the amount of ambient air to draw into the plenum, these plenums do not have bypass dampers on the bypass openings.

Kitchen Exhaust Applications

In kitchen exhaust applications, the materials of the plenum will be high temperature and will have high temperature coatings in case a grease fire occurs. These plenums will have a sloped floor and grease trap to capture any potential grease escaping through the exhaust airflow. Plenum doors are rated for 300°F so these are not supplied on high temperature applications.

Heat Recovery Units

In heat recovery units (HRUs), plenums will be double wall insulated with access doors built into the side for easy plenum access. Light kits can be installed within the plenum/HRU as an additional option as well as electrical outlets at each access door.